Efficient thermal management is critical in high-performance computing systems, particularly in AI and defence industries, where the demand for exceptional computational power often leads to high levels of heat generation.

CNC machining is pivotal in enabling the production of highly precise and complex components that manage heat effectively. By integrating advanced materials and design innovations, CNC technology continues to push the boundaries of what’s possible in thermal dynamics.

Thermal Dynamics in Electronic Components

Thermal dynamics play a crucial role in the performance and reliability of electronic components. As electronic devices operate, they generate heat due to the energy dissipated by the electronic circuits. If not managed efficiently, this heat can lead to overheating, which poses several challenges to the system, including the deterioration of components, reduced lifespan, reduced lifespan of the device, and even complete system failures.

Effective thermal management dissipates heat and maintains optimal operating temperatures. Techniques such as heat sinks, thermal pads, and cooling fans ensure that electronic systems can handle thermal loads, thereby enhancing their stability, efficiency, and longevity.

Types of Thermal Dynamics in CNC Machining

In CNC machining, various thermal dynamics solutions exist to manage heat efficiently. Each solution has a specific purpose and is essential for different applications, especially for high-performance computing systems. Here’s an overview of each:

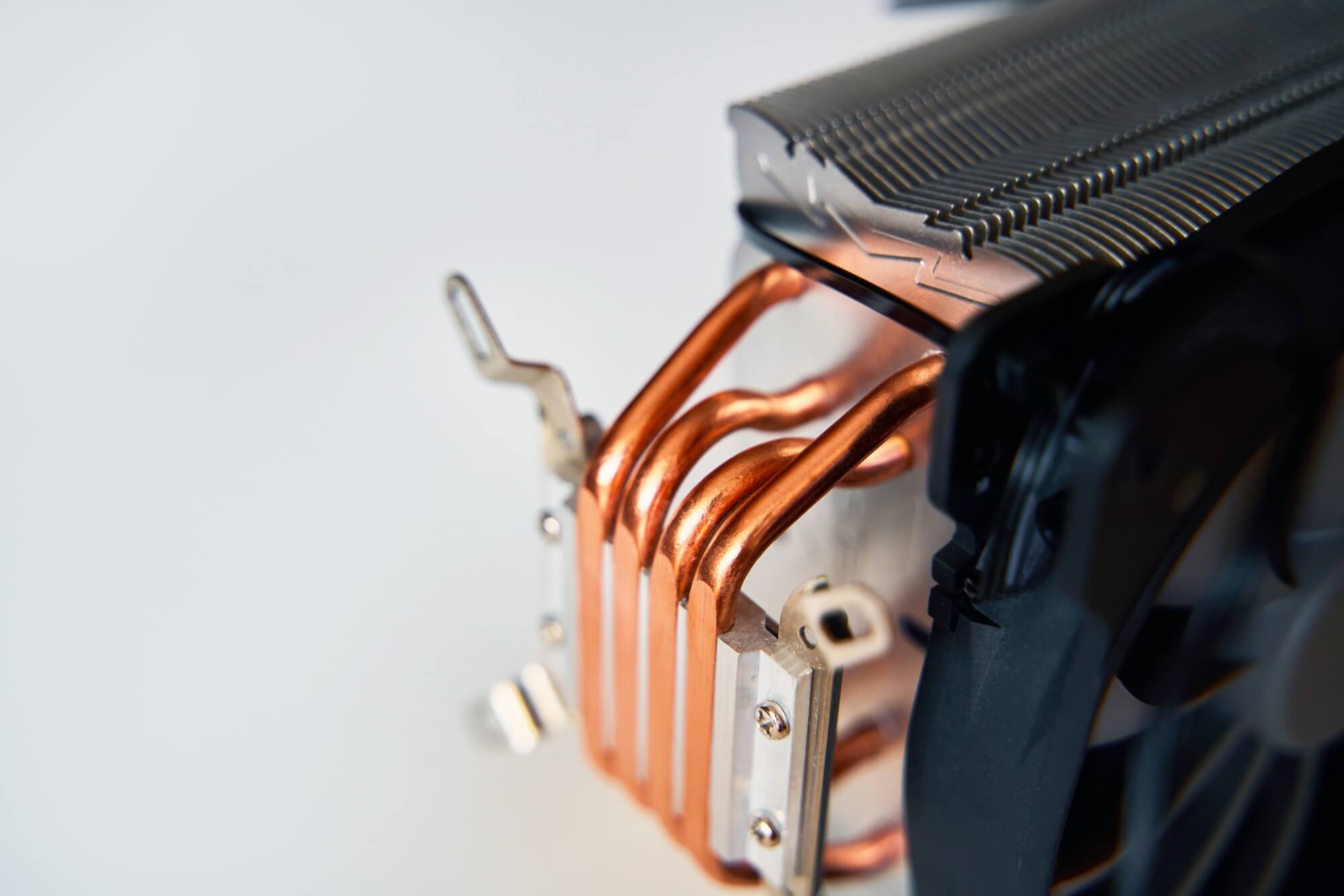

Embedded Heat Pipes

Embedded heat pipes act as heat conduits, enabling heat transfer from the source to cooler areas. CNC machining tools create the precise internal geometry required for heat pipes, ensuring they fit tightly within the components.

Heat Sinks

Heat sinks disperse heat from electronic components to the surrounding environment, typically through increased surface area. The CNC machine creates intricate fin structures and complex geometrical shapes, maximizing surface area and improving heat dissipation. CNC technology allows for precise manufacturing using high-conductivity materials like aluminum or copper.

Heat Spreaders

Heat spreaders evenly distribute heat over a larger area to prevent hotspots and improve thermal efficiency. CNC machining ensures the flatness and high-quality surface finishes required for optimal thermal contact between components.

Thermo-Electric Coolers (TECs)

TECs use the Peltier effect to move heat from one side of the device to another, creating a cooling effect. They provide precise temperature control for sensitive components. CNC machining makes the housings and mounting structures for TECs, ensuring proper alignment and thermal interface.

Liquid Cooling Systems

Liquid cooling systems transfer heat away from critical components using a circulating coolant, which is more effective than air cooling. Components made by CNC machining include cold plates, connectors, fittings, and pump housings.

Vapor Chambers

Similar to heat pipes, they have a flat, planar structure that spreads heat uniformly across a surface. They use a working fluid that evaporates and condenses within the chamber, moving heat efficiently. CNC machining can produce the thin-walled, flat structures required for vapor chambers.

Advancements in Defence and Ruggedized Computing

Thermal management is critical to defence applications due to the demanding operating environments and the need for sustained performance of sensitive electronics and weaponry.

Here’s an overview of the demand for robust thermal management in defence applications and how CNC machining meets these requirements:

Modern defence systems, such as radar, avionics, and laser systems, generate significant heat from high power densities. Efficient thermal management prevents overheating and ensures reliable operation. This equipment often operates in harsh environments, and thermal management ensures performance stability.

CNC machining, a technology that plays a pivotal role in meeting the demanding requirements of defence applications, allows the creation of complex geometries essential for advanced thermal management components such as heat sinks, heat pipes, and cold plates. CNC machining tools can work with a wide range of high-performance materials, including titanium, high-grade aluminum, and copper.

The precision and repeatability of CNC machining, a hallmark of this technology, ensure that thermal management components meet tight tolerances every time, which is crucial for maintaining proper thermal contact and efficient heat transfer.

Reach Out to the Pros at Ben Machine

CNC machining is central to advancing thermal dynamics by enabling the precise and consistent production of high-performance thermal management components. CNC technology ensures these complex parts meet the stringent demands of industries such as high-performance computing, artificial intelligence, and defence. The ability to work with high-performance materials, create intricate geometries, and maintain tight tolerances makes CNC machining indispensable in developing robust, efficient, and reliable thermal solutions.

If you want to enhance thermal management in your specific applications, contact the experts at Ben Machine and learn more about how CNC machining can be tailored to meet your unique needs. They will help you explore cutting-edge thermal solutions designed to keep your systems running at peak performance, no matter the challenge.