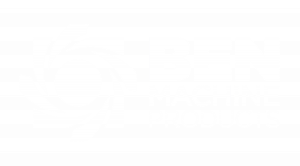

Maximizing the Efficiency of CNC Machining

Our continued success at Ben Machine depends entirely on our ability to take care of our customers. While that obviously translates to our ability to produce top-quality CNC machine parts, that ability often relies on things that happen around the edges -the things that allow us to be efficient. There is so much that goes […]

Techniques to Improve the Speed of the CNC Machining Process

New product development is one of those things that seems to take forever, and there’s just no way around it. It’s one of those “haste makes waste” situations. You double and triple-check everything when every dimension matters on complex parts. Then when the CNC experts have to turn the product plans into manufacturing plans, a […]

Optimizing machine part design for CNC production

It’s time to roll out a new product. Your engineers are working on the details of the design now, laying out every dimension on every part and specifying every component. They are designing your product to do what you need and have all the features you want. Having engineers on staff is a tremendous cost-saving, […]

Common CNC Machining Challenges and How to Tackle Them

Your average person on the street can’t walk into a CNC machining shop and run a 5-axis CNC mill. Today’s CNC machines are incredibly complicated. They take a tremendous amount of training just to start to use one, and the learning never really ends. Even trained CNC operators have to learn new machines before they […]

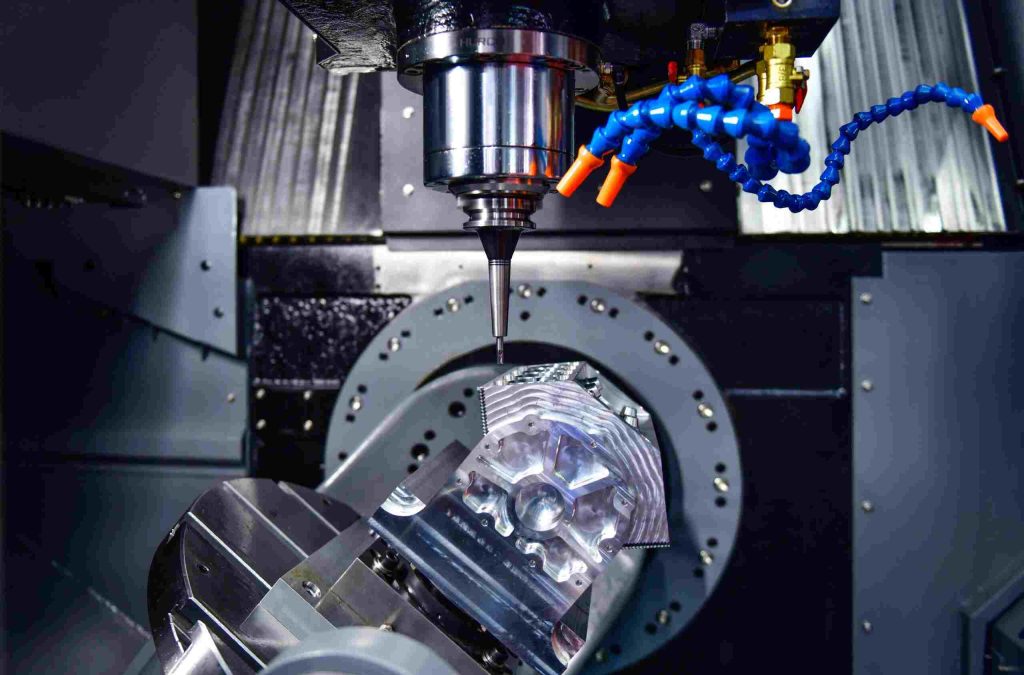

Factors to Consider in Selecting the Best Metals for CNC Machining Projects

Every part of every product has a job to do, and how well it does that job depends on several factors, starting with what it’s made of. Whether it’s a fin in a jet engine, a heat shield, or the hood ornament on a car, the metal in it is selected to meet certain requirements. […]

Machining Services For Custom Machined Parts For Every Industry

There’s one truism about advancements in the last seventy years. In just about every field, new developments have almost always pushed boundaries -new materials, new manufacturing techniques, and new size limits (smaller, of course). In the early days of any major development, the work generally falls on the most advanced and innovative people. They’re the […]

CNC Machining: Manufacturing To Customer’s Requirements and Just-In-Time

The Army figured out long ago that supply and logistics is both complicated and important enough they created the Quartermaster Corps to keep soldiers supplied. Good CNC machine shops get that. Every new CNC machining job starts one of two ways -with raw materials or with a casting that roughs in the part’s shape. Either […]

Sheet Metal Fabrication: Making Complex Metal Structures

New technologies are continuing to produce new lightweight metal alloys for the military and aerospace industries. Artificial intelligence is developing new metal chemistries and finish techniques to dial in performance gains. This is resulting in a much wider variety of alloy types being used in modern ground and air equipment. This pushes Ben Machine […]

Control of Shape and Performance for Fabrication of Precision Metal Parts

Poor quality control can bring a business to its knees. The liabilities and exposures from poor quality control extend past money, all the way to customer safety and satisfaction. To counter poor quality, Ben Machine is certified to the requirements of the AS9100 aerospace quality standard. This serves as a set of standards governing manufacturing […]

What All CNC Machining Buyers and Purchase Directors Need To Know (A Guide)

Your company’s new product is going to require CNC machining. It’s on you to find the machine shop that best fits your needs. You may know nothing about CNC machining, and it may seem impossibly complicated, but it’s not. You already know the basic business principles to watch for, and that’s half the battle. This […]