Low-volume production refers to manufacturing a relatively small number of units—typically between 10 and 500—though exact quantities can vary depending on the industry and technology involved.

Manufacturers often use a low-volume approach to bridge the gap between prototyping and mass production. Companies also use it when products are extremely expensive and sales volumes are low by nature.

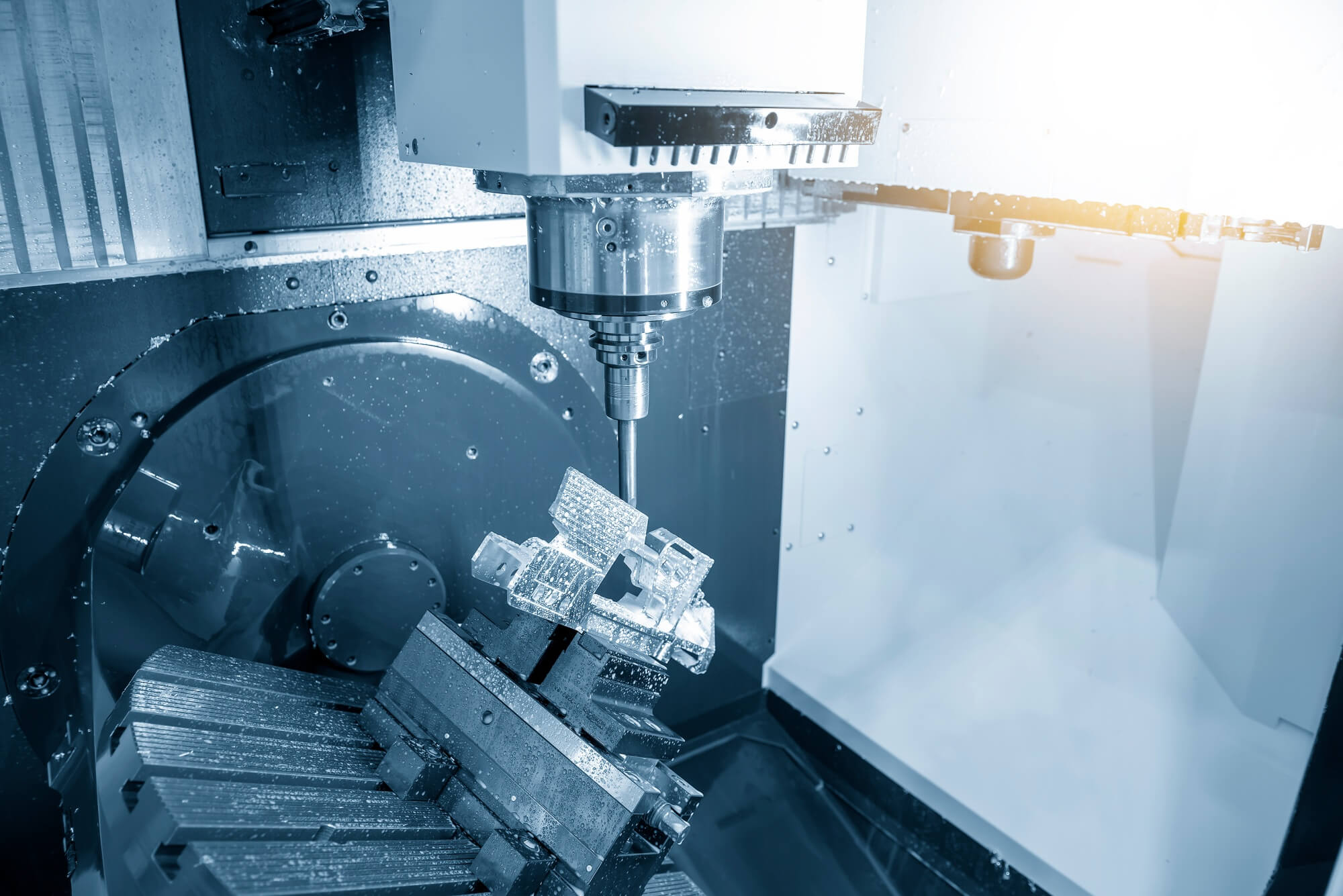

Whatever the reason for using it, low-volume production often leverages flexible manufacturing technologies such as CNC machining, which require less upfront investment in tooling and setup compared to traditional high-volume production methods.

Despite its flexibility, low-volume production has hidden costs that can add up quickly.

The Hidden Costs in Low-Volume Production

While low-volume production offers benefits like flexibility, faster market response, and reduced inventory requirements, it also comes with several hidden or less obvious costs:

Tool Changes

Low-volume production often involves frequent tool changes to accommodate different part designs. Each change introduces downtime, increases wear on equipment, and reduces overall machine efficiency. As the number of unique parts increases, so do the labour and time costs associated with switching tools—driving up the overall cost per part.

Setup Times

Short production runs typically require more frequent setups. Each batch may need custom machine adjustments, alignment, and test runs, all of which add to labour time and reduce machine availability. These setup demands can significantly impact productivity and are a key factor in the higher per-unit cost of low-volume manufacturing.

Quality Control

In low-volume production, maintaining consistent quality can be more complex due to the limited repetition of each part. Each new setup or part variation introduces the potential for inconsistency, requiring more rigorous inspection and testing. This added attention can increase labour and equipment costs, especially if issues lead to rework, scrap, or warranty claims.

How to Mitigate Hidden Costs

While low-volume production can introduce challenges like increased setup time, tool changes, and quality control demands, these costs aren’t unavoidable. By strategically investing in technology and optimizing processes, manufacturers can improve efficiency, maintain quality, and reduce overall expenses.

Here are a few key approaches to help minimize the hidden costs associated with low-volume production.

Invest in Technology

Modern CNC machines are designed with flexibility in mind. High-precision, multi-axis machines can handle a variety of operations in a single setup, significantly reducing the need for frequent tool changes. Many also come equipped with automatic tool changers and intelligent control systems that streamline the transition between different jobs.

In addition, automated loading and unloading systems can dramatically cut setup time and manual handling—key factors in low-volume environments. By reducing reliance on manual labour for routine tasks, manufacturers can lower lead times, improve consistency, and enhance overall profitability.

Process Optimization

Applying lean manufacturing principles is essential in reducing the inefficiencies that often come with short-run production. By minimizing downtime between tool changes and improving overall setup workflows, businesses can unlock substantial productivity gains.

One effective strategy is to standardize tooling and fixtures wherever possible. Using modular setups or quick-change tooling allows for faster transitions between parts and simplifies the operator’s tasks. Mapping out and refining the changeover process—using tools like SMED (Single-Minute Exchange of Die)—can lead to dramatic reductions in non-productive time.

Quality Control Innovations

In low-volume production, ensuring consistent quality can be more complex due to frequent changes in parts and processes. To address this, integrating advanced quality control technologies is key.

Real-time measurement tools, such as in-process probing and automated inspection systems, allow for immediate detection of defects during production. This proactive approach reduces the need for extensive post-production checks and helps prevent costly rework or scrap.

Additionally, process monitoring and data analytics tools can uncover recurring issues and highlight opportunities for improvement. By identifying defect trends early, manufacturers can adjust processes in real-time, improving part consistency and reducing the long-term cost of quality control.

The Benefits of Mitigating Hidden Costs

Reducing hidden costs improves operational efficiency and profit margins in low-volume production. The optimized processes lead to quicker turnaround times, higher product quality, and lower production costs.

Companies gain a competitive advantage as lower operational costs and higher-quality components allow manufacturers to offer more competitive pricing. Cost savings from these process improvements can be passed on to customers, attracting more business.

In Summary

Ben Machine leverages its advanced CNC technology, lean manufacturing, process optimization, and quality control innovations to mitigate hidden costs and improve efficiency during low-volume production.

High-speed, multi-axis machine tools provide increased flexibility with state-of-the-art tool changers, and faster setups reduce labour hours and downtime.

Utilizing lean principles results in standardized tooling and fixtures that enable shorter swap times and more streamlined production runs while real-time measurement and quality control tools catch defects earlier in the process and reduce post-production rework.

Process monitoring and data analytics improve quality, continuously catch defect patterns, and reduce the need for extensive inspections.

Low-volume manufacturing might be the norm at Ben Machine, but quietly accepting its hidden costs is not!