Heat management in electronic devices is challenging due to their increasing power density and miniaturization. As electronic components become more compact and powerful, they generate significant amounts of heat in a smaller space, leading to issues if not properly managed.

Combining CNC machining and aluminum’s unique properties offers significant thermal management solutions for these electronic devices and other applications.

The Challenge of Heat in Electronics

The challenges of heat generation in electronic components include the following:

- Performance Degradation: Excessive heat can cause electronic components to operate less efficiently, reducing overall performance.

- Shortened Lifespan: High temperatures accelerate the aging of electronic components, potentially leading to premature failure.

- Reliability Issues: Overheating can cause intermittent malfunctions or complete system failures.

- Thermal Runaway: In extreme cases, uncontrolled heat buildup can lead to thermal runaway, potentially causing fires or explosions.

- Thermal Cross-Talk: In tightly packed devices, heat from one component can affect nearby components, leading to uneven temperatures and potential failures.

Aluminum: A Thermal Conductor for Electronic Innovation

Aluminum’s unique properties help with electronics thermal management. Here are some of these properties:

- Thermal Conduction: Aluminum has excellent thermal conductivity, with a value of approximately 237 W/mK.

- Lightweight Nature: Aluminum’s low density makes it ideal for weight-related applications like portable devices or aerospace electronics.

- Cost-Effectiveness: Compared to other materials like copper, aluminum is relatively inexpensive, making it a cost-effective solution.

- Versatility: Aluminum can be easily extruded, machined, and shaped into various forms, allowing for the creation of complex heat sinks optimized for specific applications.

Aluminum is the material of choice for manufacturing heat sinks, embedded heat pipes, enclosures, and cooling fins, all of which help with heat dissipation.

CNC Machining: Precision for Optimal Heat Dissipation

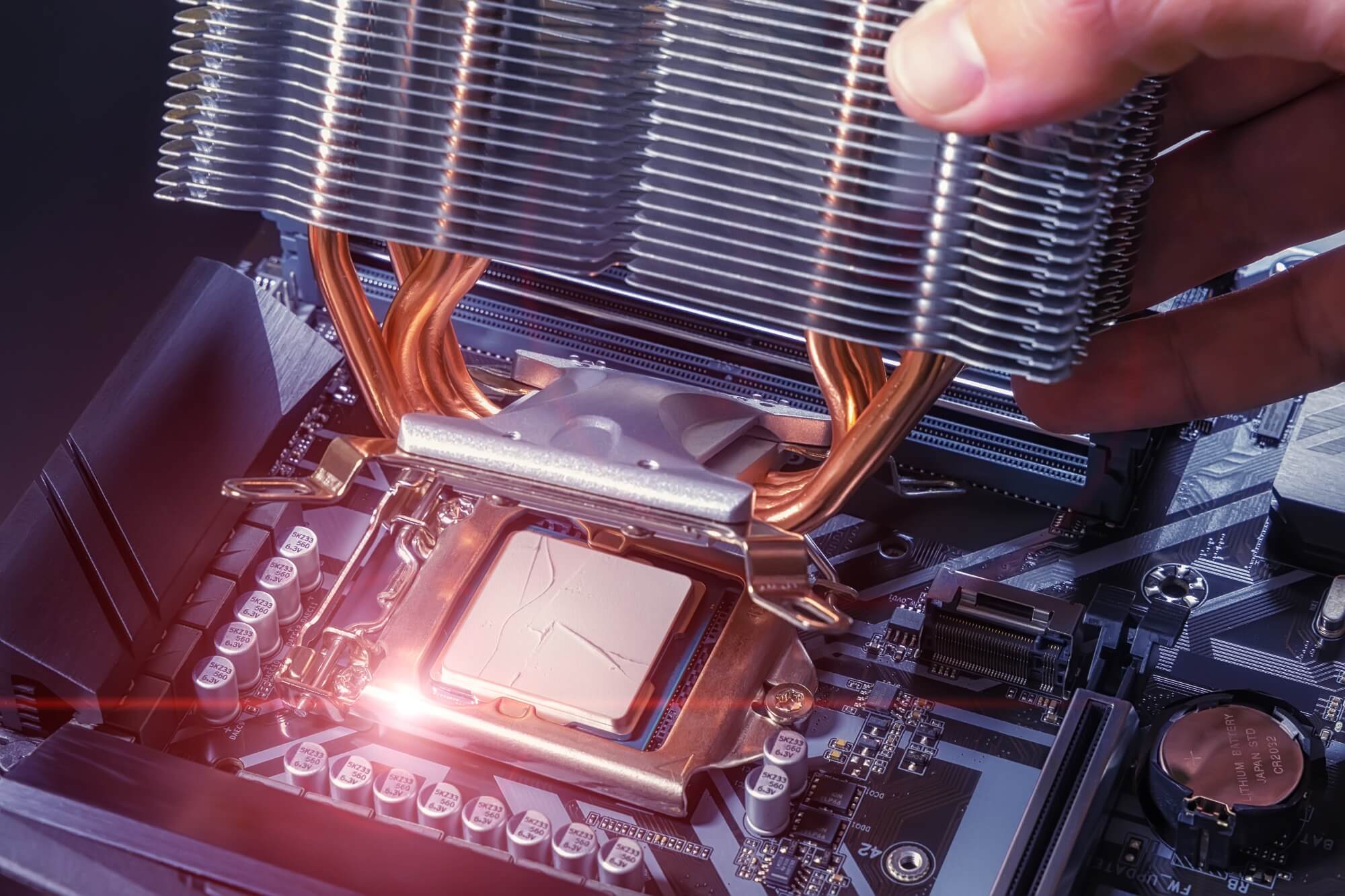

Combining CNC precision and aluminum’s inherent properties results in superior heat dissipation. CNC machining can create large surface areas within compact designs, enhancing heat transfer efficiency. At the same time, precisely machined channels and fin arrangements facilitate better airflow, which is crucial for convective heat transfer.

CNC machining enables the creation of intricate and optimized heat sink designs in aluminum, which results in an effective cooling technique.

Applications of Aluminum for Heat Management

Aluminum is widely used in heat management across various industries, especially in CNC-machined components. In electric vehicles (EVs), aluminum heat sinks are integral to the cooling systems. Its high thermal conductivity helps dissipate heat generated by battery cells and electric motors, ensuring optimal performance and extending system longevity.

Beyond EVs, aluminum plays a key role in other industries. In electronics, it’s used in heat sinks, enclosures, and embedded heat pipes to prevent overheating of sensitive components. The aerospace sector also benefits from aluminum’s thermal properties, using it in avionics and critical systems to maintain performance under high temperatures.

Aluminum’s versatility extends to renewable energy, where it’s used in solar inverters and wind turbines to manage heat effectively. Its ability to manage heat efficiently across various applications makes aluminum an ideal material for modern thermal solutions.

By leveraging precision machining, manufacturers can create lightweight, high-performance heat management solutions. These components enhance energy efficiency and support the reliable operation of a wide range of systems and devices.

Wrapping Up

CNC machining can produce aluminum components with significantly improved thermal management properties. For instance, in the electronics industry, CNC-machined aluminum heat sinks prevent overheating and ensure the longevity of devices.

The precision of CNC machining allows for the creation of complex geometries and intricate parts that optimize heat dissipation, supporting a faster time-to-market for new products.

Talk to the CNC-machining specialists at Ben Machine for expert manufacturing solutions focused on thermal management.